Alfie Rowe, Managing Director at Armorduct, explains the importance of building strong partnerships and how these relationships can meet contractors’ changing needs and boost sales.

As pressure grows on electrical contractors to reduce costs and improve sustainability, cable management manufacturers and wholesalers have a crucial role to play. By working as partners, and approaching contractors’ needs more proactively and flexibly, there is the potential to create solutions that provide greater value, minimise environmental impact and ensure repeat custom.

A step ahead

Early engagement with contractors is key. Cable management manufacturers have to invest the time in monitoring new construction projects and nurturing potential leads to open early lines of communication. Taking a proactive approach means that cable management requirements can be discussed from the project’s outset. By asking the right questions, we can then advise on the most appropriate solution, ensuring it will meet exact needs and overcome any possible constraints or challenges.

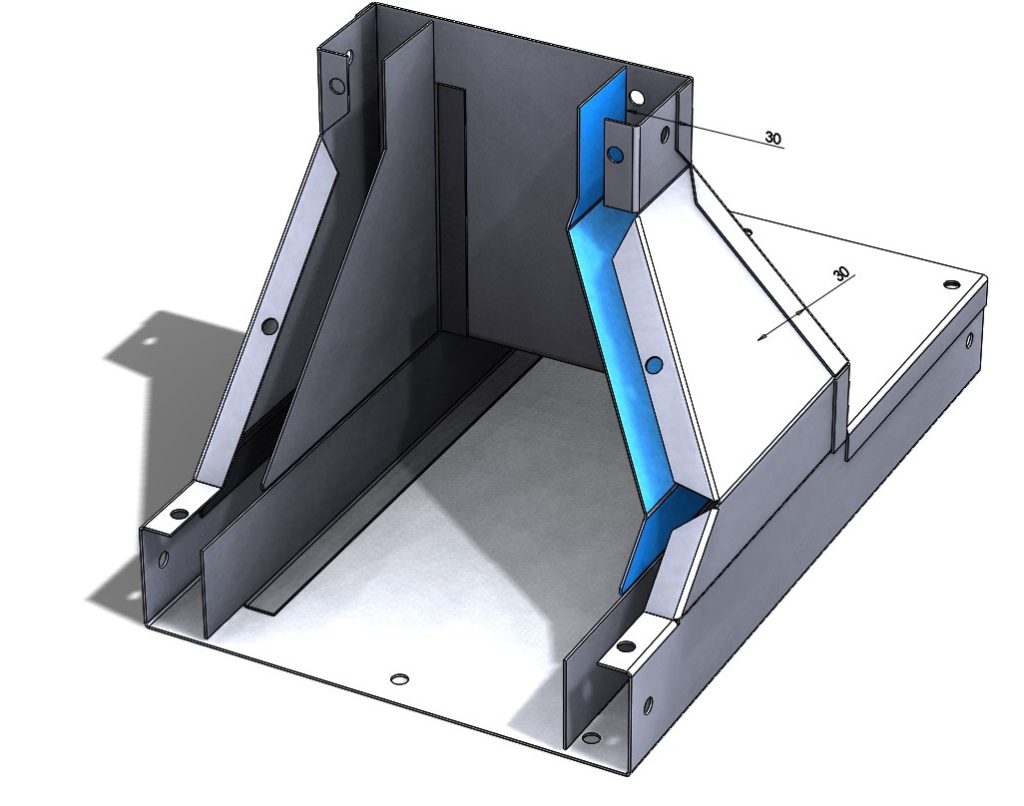

Through these discussions, we can also establish what bespoke items may be required alongside standard cable management components. To deliver a tailored product, manufacturers must be flexible, willing to take on a challenge, and have the inhouse resources to deliver large scale solutions as well as smaller product variations.

At Armorduct for example, we have invested in our production facilities, creating a specialist section within our manufacturing plant dedicated to producing bespoke products. This enables us to dramatically reduce lead times for these items and ensures the manufacture of our off-the-shelf ranges is not negatively impacted.

We have also deployed dedicated experts from the computer aided design (CAD) team to work on bespoke solutions and value-engineer standard production items to provide greater efficiencies.

A further benefit of proactive and early engagement with contractors is the potential to identify opportunities for manufacturing off-site. Prefabricated containment modules and risers offer many advantages for contractors across sectors. From bracketry through to fully populated frames, there is a vast range of modular solutions which can save costs, time, waste and labour while offering installers known embodied carbon content. Prefabrication can also support health and safety legislation requirements as there is no need for hot works on site.

As part of the Hudson Group, Armorduct can join forces with sister company RMS to provide modular containment systems to exact specifications, providing a one-stop-shop for contractors’ cable management needs and maximising on site productivity.

Mutual benefits

When creating bespoke or modular cable management solutions for contractors, manufacturers can’t work in silos. To provide the best possible solution and service, strong partnerships with wholesalers are crucial.

In addition to containment, a wide variety of ancillary products, ranging from sockets through to cabling, will be required to meet the wider electrical brief. A close business relationship, that sees manufacturers share knowledge and information, will create opportunities for wholesalers to maximise sales, streamline the supply chain and improve the customer experience throughout the project.

Effective communication between suppliers, wholesalers and contractors is key to this strategy. The ability to swiftly contact design engineers, technical experts and sales teams who can promptly answer questions and address any issues is a critical factor in completing projects on time. To meet this need, Armorduct has set up a major projects team comprising experts with more than 100 years’ combined industry experience. Their role is to liaise with all parties and provide a personal service. This builds trust, makes the life of the wholesaler easier and guides the project more successfully.

A collaborative approach will also ensure manufacturers and wholesalers are aligned in terms of their environmental commitments. The need for more sustainable construction means a growing number of electrical contractors will prioritise partners committed to minimising their impact on the environment. This requires a focus on sustainability throughout the whole product lifecycle.

Manufacturers are responding by implementing a range of initiatives, including advanced metal recycling facilities. These enable offcuts of materials to be reused in other manufacturing processes. As well as reducing waste during production, this process provides a fixed carbon cost.

A win-win

Greater efficiency, quality and sustainability will continue to move up the priority list for contractors. This is creating opportunities for proactive cable management manufacturers with the skills, resources and knowledge to react quickly to contractors’ specific requirements. Whether that involves a bespoke, off-site or standard solution, strong partnerships with wholesalers are a critical component in the whole process. A collaborative approach that goes beyond a sales transaction will create benefits for all parties, including the potential for repeat business and a stronger bottom line.

For more information, click here