Brett Smyth, General Manager EMEA of Ideal Industries discusses the quality, integrity and safety implications of choosing counterfeit connectors for electrical terminations.

Everyone loves a bargain. In the electrical sector, where margins are often tight, it’s not surprising that contractors look for opportunities to reduce overheads wherever possible by choosing value for money products and after the tumultuous year we had in 2020, the drive to make cost-effective choices has never been greater.

But there’s a huge difference between value for money and cheap. While, financially, choosing the lowest cost option may seem like the right decision, unbranded consumables could have negative commercial implications that cost the contractor much more than the small savings they gain. When it comes to cable connectors, for example, the pennies contractors might save by using unbranded products could result in installation integrity and safety issues, which could affect their prospects of repeat business and even their reputation.

For the wholesaler meanwhile, there is no margin to be gained by selling low-cost counterfeit goods. Conversely, however, there is an opportunity to add value to customer relationships by recommending genuine, quality assured branded products which provide value for money.

Branded or unbranded

If something looks the same as a branded item and does the same job, it must be the same right? Wrong – and selling counterfeit connectors in place of trusted, branded products can have very short term benefits for contractors and wholesalers alike.

Branded products are produced thanks to expertise in design, commitment to innovation and investment in testing. This meticulous research and development process ensures the items that reach the shelf are fit for purpose, easy to use and provide a robust, durable solution throughout the service life of the installation.

That design is protected by a patent, ensuring the company that has invested in leading edge product development can continue investing in innovation. This, in turn, brings new products to market, resulting in access to faster, easier and more consistent installation methods for contractors, along with an enhanced product range for wholesalers.

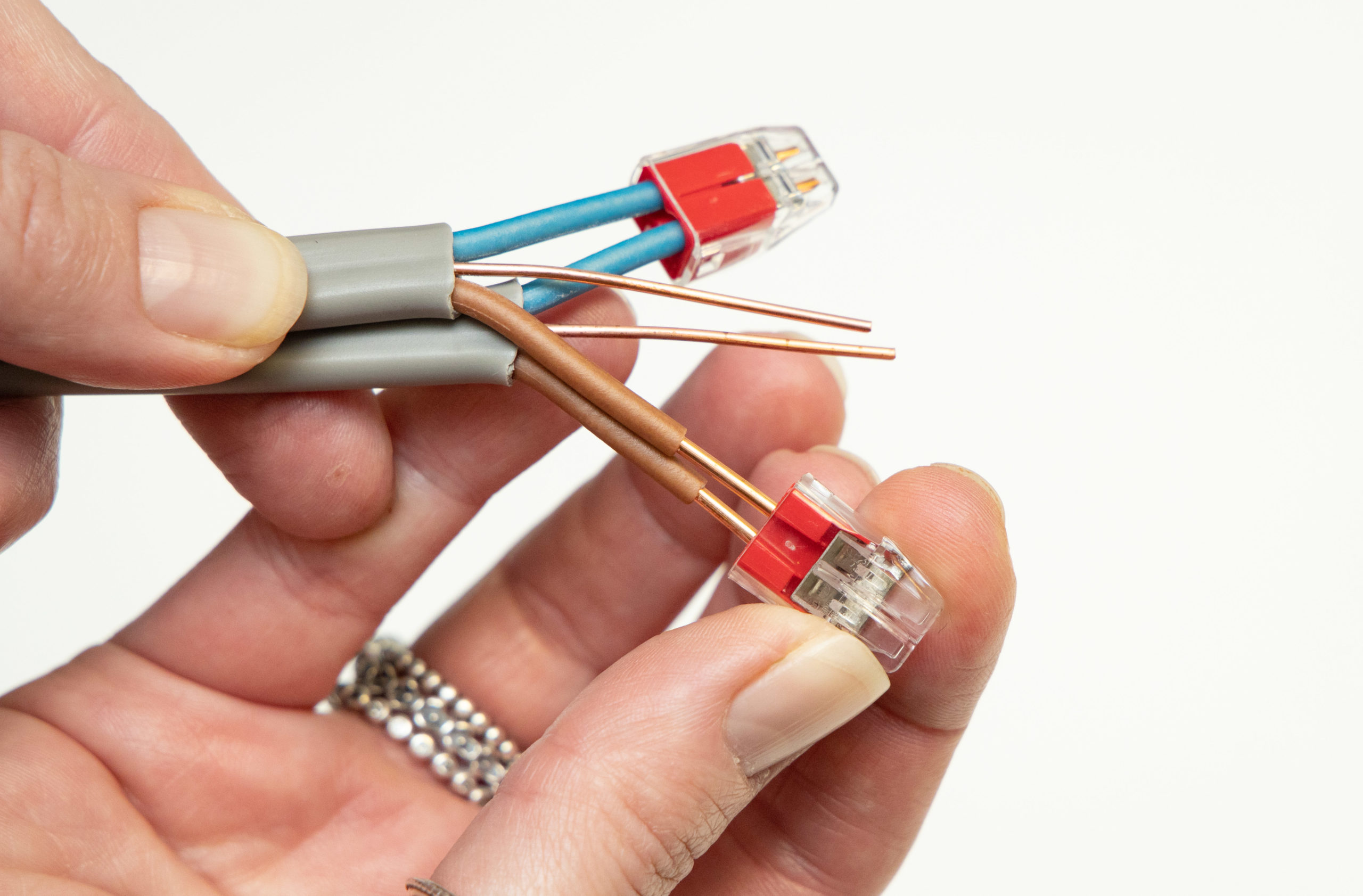

Ideal Industries is amongst just a handful of brands that has invested in a detailed product development process for push-in and lever connectors, resulting in tested and proven products that offer consistent product quality. In-house manufacturing ensures that quality assurance protocols are in place to underpin product confidence and electricians using a branded item like this can be certain it will perform as expected, during installation and beyond, which means repeat business for wholesalers.

Cut price, unbranded connectors, on the other hand, not only contravene patent law, but are often cheaply produced, which could result in the contractor choosing to go elsewhere for supplies next time.

Counterfeit products

If the product looks the same and feels the same, what’s the difference between a branded product and an unbranded one? The answer is, even when it’s a commodity item like push-in or lever connectors, reduced quality can compromise an installation in terms of quality, safety and programme delays.

The cheaper materials used in the manufacture of counterfeit goods, poor quality control and lack of testing all mean that product integrity is often an issue. Counterfeit connectors may break easily when used on site, resulting in rising costs from wastage and increased installation times for contractors. As a result, choosing a cheap imitation of innovation that was originally designed by a trusted brand could actually cost contractors more and damage their trust in the wholesaler.

Arguably worse than the risk of breakage, is the risk of cracking. A cheap alternative to a branded connector may seem to be performing well enough on site but, because design values and materials are not up to standard, cracking is not uncommon and could go unnoticed. This can be a cause of snagging issues, call backs and potential safety hazards, all of which are both costly to contractors and damaging to their trust in the wholesaler.

The right choices

It’s been a tough commercial climate for all aspects of the electrical delivery chain over the past few months and saving money where possible has been key to commercial resilience. Sometimes, however, it pays to advise customers on prioritising quality and value over lowest price. It can be hard to spot counterfeit connectors because they are purposefully manufactured to look like leading brands.

Branded products like Ideal Industries’ In-Sure range of push-in and lever connectors are clearly labelled and packaged ensuring wholesalers can be confident they are offering their customers value for money, proven products providing both quality assurance and competitive pricing.

For further information on connectors click here