Jake Green, Group Technical Engagement Manager at Scolmore Group, takes a look at earth electrodes and the relevant code of practice associated with their application.

BS 7430: 2011+A1:2015 is a code of practice for protective earthing of electrical installations. This standard is closely linked to the requirements of BS 7671, where relevant, and both should be considered when dealing with earthing requirements.

BS 7430 provides recommendations on meeting the requirements for earthing of electrical installations. The three areas include; protective earthing of low voltage installations, the interface between LV and HV substations (11kV/400V), and protective earthing and changeover switch arrangements for generators.

Earth electrodes

Earthing of a system (or equipment) requires a physical connection to the general mass of Earth. The connection should have resistance such that any means of protection will operate as designed.

There are many factors that will impinge upon the resistance of the connection to Earth. These will include the nature and properties of the soil within a location, rainfall, and the nature of the earth electrode. For example, light clay soils will have a relatively low resistivity (c 5 Wm), whilst granite has a resistivity in the region of 1000 Wm.

The presence of low volumes of rainfall will also have a significant impact on soil resistivity. For example, clay soil in locations having a normal rainfall exceeding 500mm/year has a typical resistivity in the region of 5 – 20 Wm, whilst in locations having a rainfall less than 250 mm will have a resistivity range of 10 – 100 Wm.

An earthing system should be of high integrity and robust construction. The use of an Earthing system using earth electrodes relies on the resilience of the earth electrode(s) for the safe functioning of the protection system within an installation.

The types of earth electrode can vary. Regulation 542.2.2 of BS 7671 recognises seven permitted types of earth electrode, including earth rods or pipes, tapes or wires, earth plates and the like. The most commonly selected earth electrode is the rod.

Application

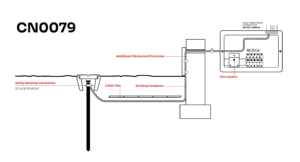

Earth electrodes are to be (or may need to be) installed for: TT and IT Earthing systems, earthed generator sets, to conform to Regulation 411.4.2, swimming pools having a PME earthing facility, agricultural premises, mobile or transportable units, EV charging installations, and prosuming installations.

Where earth electrodes are installed, Regulation 542.2.1 requires that the earth electrode can withstand damage and take account of possible increases in resistance due to corrosion. The means of connection must be electrically and mechanically sound (526.1) and be accessible for inspection, testing and maintenance (526.3).

Earth electrode resistance

Depending on the requirement of a particular regulation, the resistance of the earth electrode will have a maximum permitted value. For example, for a TT Earthing system, Regulation 411.5.3 details the conditions that must exist where an RCD is used for fault protection. This regulation requires the disconnection time to be limited to:

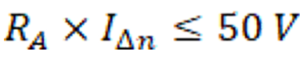

0.2 s for final circuits (411.3.2.2) or 1 s for distribution circuits (411.3.2.4), and  .

.

Table 41.5 details the maximum earth fault loop impedances permitted for a range of values of RCDs.

However, due to the risks associated with drying and freezing conditions, BS 7430 references a note under Table 41.5 of BS 7671 referencing a value in excess of 200 W not being stable.

The earth electrode resistance is less a function of the diameter of the electrode and more to do with the depth that the electrode is driven, the ability of the rod to be driven into the ground without damage, and the number of electrodes connected in parallel.

Clause 9.5.3 in BS 7430 details how the resistance of rod electrodes may be calculated. Where rod electrodes are to be paralleled to reduce the resistance, rods will have to be separated by at least 6m to gain the maximum benefit (Figure 14a BS 7430). The formulae to determine the resistance of a single electrode and parallel electrodes are detailed in clauses 9.5.3 and 9.5.4 of BS 7430. Clause 9 of BS 7430 details many more methods of connecting electrodes, and reference should be made to this standard.

Conclusion

Earth electrodes are a necessary requirement for many parts of BS 7671. BS 7430 details the recommendations needed to ensure earth electrodes are correctly selected and installed.

Unicrimp, part of the Scolmore Group of companies, supplies all the necessary elements for the safe installation of rod type earth electrodes.

For more information, click here