Models for Class 2 electrical device connections should be IP68 and IP69K-rated, fully submersible and saline resistant for exterior projects, says Andrew Ferny, Wholesale Director, Hylec-APL.

With Spring arriving in the UK, now’s the peak time for starting on outdoor projects. For the residential sector many contractors are likely to be starting on jobs like garden lighting and pond and pool installations. Commercial installers will be looking at multiple projects involving exposure to the elements, ranging from outdoor lighting in commercial premises such as hotel terraces to large-scale public installations. The overriding requirement for outdoor power is a safe installation that can be signed off with full confidence that the components selected are able to provide continuity of connection for extended periods of time. Connectors for outdoor power should have the correct IP rating and be robust and reliable. Ease of installation in what can sometimes be challenging working conditions is also important!

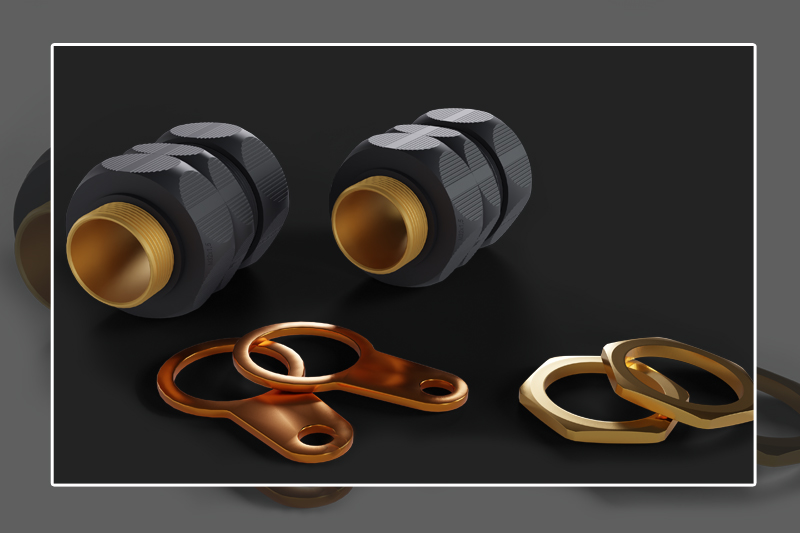

Connectors for outdoor power usually rely on a sealing system or are gel-filled. With a huge range of applications including marine, architectural illumination, signage and commercial underwater lighting, how can wholesalers know the products they are stocking will suit their customers’ needs? The Weatherproof connector range is a good example, with resistance to extreme conditions including rain, flood, tide, sand, snow, ice, industrial washes, chemicals, oils and grease.

The IP68 and IP69K models can be permanently submerged under water, including sea water, and also withstand high pressure water jets as well as dirt and dust. Installations around the world include architectural lighting, street lighting, underwater lighting, illumination of road signs and billboards and the connection of interior and exterior Class 2 electrical devices.

Bridging the gap

Just one very visible example was the re-illumination of Blackfriars Bridge in London when the original underlighting partially failed after some years, leaving whole sections of the bridge unlit. The contractors for the project, Armadillo Lighting, discovered that the problem was not the LEDs but rather that the connectors used had failed due to corrosion, water ingress and rust. The whole underlighting system had to be completely re-wired, a complex job involving technicians abseiling down from the bridge, supported by supply and safety boats. Top-quality waterproof connectors certified to IP68, clip-in style connectors and a wide choice of accessories were required.

Install ease and speed were critical in such challenging conditions. Weatherproof TH392 connectors from Hylec were selected, as their proprietary system provides total protection against permanent submersion and blocks moisture transmission across terminals. The quick push-pull connection feature saved time and Weatherproof connector TH391 end cap covers protected the whole line at the end of each working day throughout the project until contractors returned the next.

All the attributes

A solution found for an industrial customer’s range of industrial fan units demonstrates the versatility of the Weatherproof range. Installed in situations exposed to outside elements as well as interior humid atmospheres, a simple connection system was needed that obviated any necessity for installers to access the interior of the fan control unit. Again, the Weatherproof range had all the attributes required, being saline resistant, flame retardant to UL94 V0/V2 and vibration resistant as well as rated up to IP68 and IK08 for impact resistance. The fans are now supplied with the panel mount part of the Weatherproof connector factory-installed, so contractors only have to take the socket section, wire up three or four wires and mate it with the panel-mounted part.

As well as larger contracts and OEM requirements, the Weatherproof range is popular with electrical contractors for residential projects such as water features and outdoor lighting. The Weatherproof range consists of TeeTube in-line circular joint connectors in various diameters, including micro connectors for small spaces; TeePlug Plug and Socket connectors for IP67 watertight connections in up to 5m of water; the 14mm diameter Micro TeePlug (watertight up to 30m); and TeeBox junction boxes and current distributors. In addition there is the compact HTube Junction Connector 4-way pre-wired distributor for tight spaces.

Multipacks of the six most popular Weatherproof TeeTube, TeePlug and TeeBox models are packaged in distinctive black and teal, with very clear product information on the pack, detailing IP rating, number of poles, and other information to make it easy for contractors to find what they are looking for. Counter display units contain 30 multipacks and are complemented by point-of-sale materials for the wholesale trade and a wholesale catalogue.

On dry land prone to seasonal and unseasonal downpours, as well as underwater, Weatherproof connectors can be relied on to keep power connected!

To discover more click here