David Barnes, Marketing Manager at KNIPEX, explains how the GEOMAR Helmholtz Centre for Ocean Research in Kiel, Germany, is using KNIPEX tools to help develop some of the world’s most state-of-the-art underwater vehicles.

Submarine films, deep-sea horrors and documentaries about journeys to the wreck of the Titanic – people have always had a fascination with the underwater world. We’ve just visited a place where these dive boats are designed and developed. Also on board: pliers from KNIPEX!

Hostile environment

It’s dark, cold and thoroughly inhospitable down there in the depths. The ocean floor, located at 11,000m at its deepest point in the Mariana Trench, holds many secrets and provides ocean researchers around the world with mysteries they want to solve. And even if a dive does not always have to go down quite so far, from a certain depth it’s preferable to send remote-controlled robots instead of human divers. The GEOMAR Helmholtz Centre for Ocean Research in Kiel continuously develops and builds these underwater vehicles, and today we are getting a very exclusive look into the room where these dive boats are made.

Prototypes for diving operations

The Technical Manager of the technology and logistics department, Ralf Schwarz could tell an exciting story about every single machine and every underwater vehicle temporarily stowed to dry off. He first shows us the workshops housing modern CNC milling, sawing and drilling machines. This is where prototypes are built, tested, improved and repaired for the hard work ahead.

The first KNIPEX pliers we see lying on the tables look almost like they are put out on display – but no, high-quality tools are essential prerequisites for precise work. The selection and interplay of materials is especially important here, because, just like in space, the environmental conditions in the deep sea are extreme. The research that goes into them to gain new insights into the world above water, too, requires robust, sophisticated solutions.

A crawler for the seabed

Behind the gates of the large bright hall, we first see the yellow deep-sea crawler Viator, which the Helmholtz Centre for Ocean Research has developed in conjunction with space and deep-sea experts from 16 German partner institutes. The Viator had its first deep-sea mission in 2017 in the Arctic on the research icebreaker Polarstern. The unmanned crawler autonomously explores the bottom of the sea from its Mansio docking station at depths inaccessible to people.

Manned to a depth of 400m

Those who have seen deep-sea horror films like “The Abyss” in the late 80s will get goose bumps when they see the submersible Jago. It is unique in Germany and allows two scientists to view the seabed down to a depth of 400m in person. The submersible can manoeuvre freely under water and has a gripper arm for taking samples. “You can see much more clearly and completely differently underwater with your own eyes than with an HD camera,” says Ralf Schwarz.

Extreme conditions

GEOMAR also has solutions for much deeper areas of the ocean. The remote-controlled, unmanned deep-sea diving robot ROV POCA (goes down to depths of 3,000m) and its “big brother” ROV KIEL 6000 (goes down to depths of 6,000m), like the Jago, can be launched from the research vessel using large cranes at the stern but remain connected to the ship via a steel winch.

After every use under the toughest, extreme conditions, the underwater vehicles are inspected, repaired and improved in the workshop while scientists analyse the research results and collected samples.

No half measures

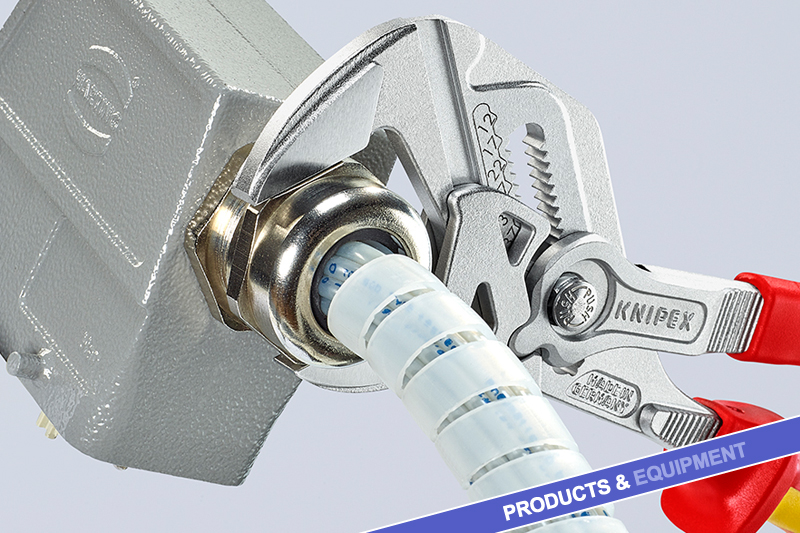

When the priority is the proper functioning of expensive research technology, especially in manned dive trips, you will see high-quality tools nearby. The GEOMAR Helmholtz Centre for Ocean Research does not take any half measures when it comes to tools. In addition to many other high-quality brands, we find many KNIPEX pliers on the work desks and in the drawers of the carts which are used here every day.

No compromises are made here in the deep sea or above water. From the heavy pipe wrench for large threads to the slender diagonal cutters for the machining of circuit boards and soldered joints, you will find half of our product range all spread out here at the workstations.

Quality for surviving

It feels like you’re in the middle of an adventure even here on land. The orange, dry-hung survival suits give you an idea of how hard the work can be out there in extreme temperatures and weather conditions. Between the big cranes, the heavy carabiners and clamps and the steel cables on big winches, we feel a sense of adventure among all this research equipment. It’s a good thing that there is a commitment to quality here on land, too. Here’s hoping the next journey into inhospitable, remote corners of the planet will be another success story and will bring us new important information about our world.

For more information, click here