Building methods are constantly changing to better profitability, efficiency and improve the carbon footprint that is left behind. AET Flexible Space is a manufacturer that is trying work on all these fronts with is underfloor air conditioning offering. PEW visited the company at its offices in Surrey to find out more about this and the opportunity for wholesalers.

Founded in 1993 as a principal worldwide distributor of the “Hiross” Flexible Space underfloor air conditioning system, the company took ownership of production in 2010 under AET Manufacturing Ltd, and developing the AET Flexible Space brand. With over 26 years of experience, the company now considers itself the undisputed authority on underfloor air conditioning technology. Here we will look at the advantages of the systems and how the wholesaler can play a key role on the success of this growing technology.

What is underfloor air conditioning?

Seems obvious, right? But it is a solution that is not too common in the UK, but rather more widely used inside offices and residential buildings in the UAE and the far east.

Basically, in the simplest terms, it makes use of the space beneath a raised access floor for the distribution of air, eliminating most ducting and pipework. It does what it says on the tin and makes the install easier for your customers, whilst saving around 15% of build space by negating the need to build in precious ceiling space. Furthermore, it allows easy access to existing systems for on-going maintenance work, again saving the precious time of the installer. For developers it could save 10% in building costs, 29% in CO2 emissions and 30% in energy costs, according to the company.

How does it work?

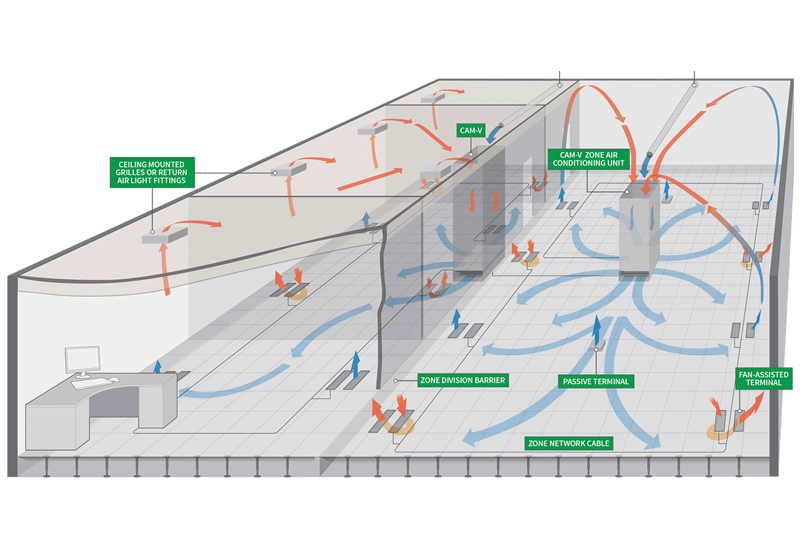

With little or no ducting, the system is installed underfloor with Zonal downflow units, or ‘CAM’ (Conditioned Air Module) that generate conditioned air which is delivered into the supply plena. Fan terminal units, or ‘Fantiles’ supply the conditioned air into the workspace. Systems can be designed to receive spent air either at floor level (CAM-C system), or at high/ceiling level (CAM-V system). The fantiles are interchangeable and can be personalised to preferred temperatures.

The techie bit

-Each floor is divided into zones of up to 300m2 depending on the potential use and occupancy density of the area.

-Each zone is supplied with chilled or warmed air by a zonal air handling unit or CAM. Conditioned air is then delivered into the space using a recessed (Fantile) or floor standing fan terminal.

-Air travels back to the CAM for re-conditioning either at floor level via the plenum (CAM-C), or at high level (CAM-V). Both CAM-C and CAM-V systems can be configured to be either chilled water (CW) or direct expansion (DX).

Case study

One Benjamin, Farringdon

Situated directly opposite the new Farringdon station, the building provides 43,562 square ft of office, retail, and residential space.

Main contractor Knight Harwood saw the opportunity at One Benjamin to redesign the original Stage 3 hot/cold aisle design and to implement AET’s underfloor air conditioning solution for the three floors of office space. Knight Harwood felt that AET’s highly flexible system would be more suited to cope with the variations in temperature across the building caused by increased/decreased sunlight.

Each of the three floors was divided into zones of up to 300m2 depending on the potential use and occupancy density of the area. Each zone is then supplied with chilled or warmed air by a CAM unit and the conditioned air is then delivered into the space using a number of fantiles.

Headroom Height was a key consideration during the design and build of One Benjamin, and by using the AET underfloor air conditioning system the contractors were able to eliminate much of the ceiling-based services and ductwork. The offices were developed to provide a sustainable workplace, and have been awarded a BREEAM ‘Excellent’ rating. The reduced amount of building materials needed for an AET underfloor system, as well as its long-term flexibility, made it an excellent choice for this project.

Wholesale benefits

Now you know what it is, how it works and where it can be applied, you’re probably wondering where you fit in. The business opportunity for the wholesaler sits in the maintenance of these systems. Due to the flexibility of the of system, those working on existing sites with Flexible Space in situ will require spare parts and additional or replacement units, AC to EC fan upgrades for CAM downflow units and controls upgrades for existing systems.

The long term goal for the company is to make these parts available for distribution partners to come on board and help grow the success of the company. Whilst the growth of the company continues, underfloor air conditioning, with its many benefits to your customer working on it, is definitely a ‘cool’ idea worth considering.

For further information:

To learn more about AET Flexible Space solutions, and potential collaboration, click here.