Alfie Rowe, managing director at Armorduct Systems, explains how by working closely together a manufacturer and wholesaler can become an integral part of an overall project team and why, in the current climate, this is vital in ensuring the prompt and accurate delivery of cable management solutions.

Construction output remains strong and this is continuing to drive demand for cable management products that can meet customers’ needs – whatever they might be. The ability to react quickly to specific requirements relies on close cooperation between a manufacturer and wholesaler, and this relationship can provide peace of mind that the right products will get to an electrical contractor on time and to the right specifications.

Sense check

On the face of it, manufacturers and wholesalers should be a match made in heaven. Without distributors, manufacturers would struggle to get their products to customers and without manufacturers, wholesalers would have nothing to sell. Given that they are mutually reliant upon one another, it makes sense for both parties to forge a relationship that is as close and cooperative as possible. This is especially the case since getting the right products and solutions to contractors quickly and efficiently will ensure repeat custom. In short, everyone’s a winner!

It is therefore a mystery why some manufacturers and wholesalers continue to operate in separate silos, don’t support each other, decline to strategise together and fail to provide a better customer experience. While every company has its own unique corporate ethos, objectives and goals, it is the responsibility of both parties to work together to understand their respective needs and overcome any challenges in their trading relationship. At the end of the day, a strong relationship improves performance for both partners through providing a better customer experience and more successful support for projects.

Two-way street

A key part in ensuring a more productive relationship is to understand how the roles of manufacturers and wholesalers differ but also how they can complement each other. Far from being the ‘middle men’, wholesalers are the customer-facing experts, while manufacturers are focused on designing, developing and producing products that meet the needs of end users.

There is no substitute for a genuine, responsive and personal service. Effective communication between suppliers, wholesalers and contractors has never been more important and being able to contact design engineers, technical experts and sales teams who can promptly answer questions and address any issues helps ensure that a project is completed on time.

Manufacturers and wholesalers should adopt an inclusive approach toward each other, exchanging knowledge and information wherever and whenever possible. By sharing mutual goals, they are more likely to be motivated to help each other and create a lasting collaboration that will be mutually beneficial for both parties. Ultimately, the goal should be to transform a purely transactional relationship into one of trusted partnership, which reduces risk for the parties involved and gives them peace of mind that they won’t be let down or have any unwelcome surprises.

Speculate to accumulate

Although forging closer business relationships can certainly make the route to market smoother, the importance of providing electrical contractors with innovative solutions that meet an increasingly diverse range of applications should not be underestimated. Manufacturers that continually invest in their production facilities are able not only to produce bespoke products but engineer off-the-shelf solutions that provide added value.

Leading cable management manufacturers are responding to this demand by setting up major projects teams that liaise with all parties and provide a personal service. Electrical contractors working in a wide variety of sectors, whether data centres, the Ministry of Defence, healthcare, education or distribution hubs, are benefitting from this approach, which offers a ready source of help and advice. This builds trust, makes the life of the wholesaler easier and guides the project more successfully.

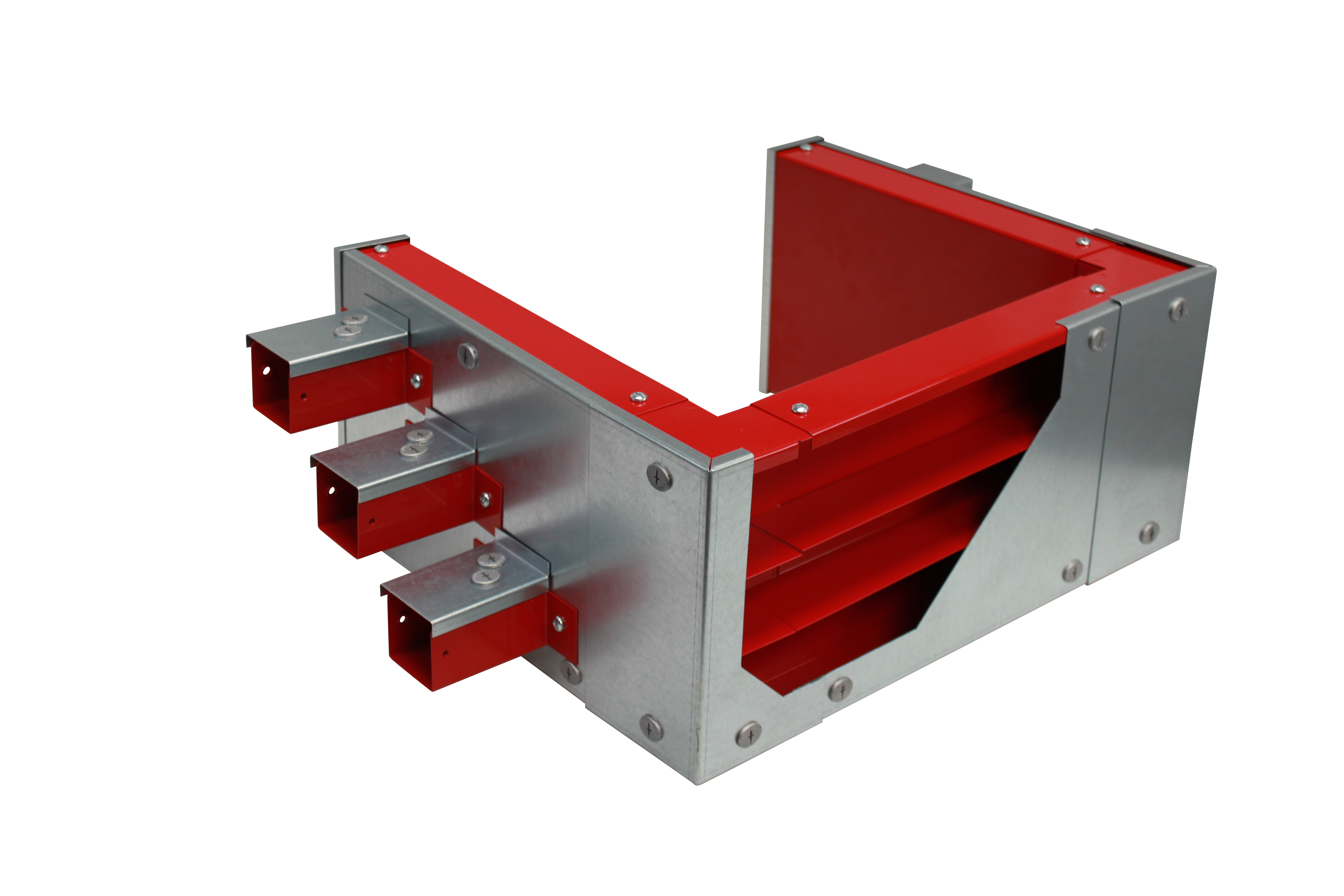

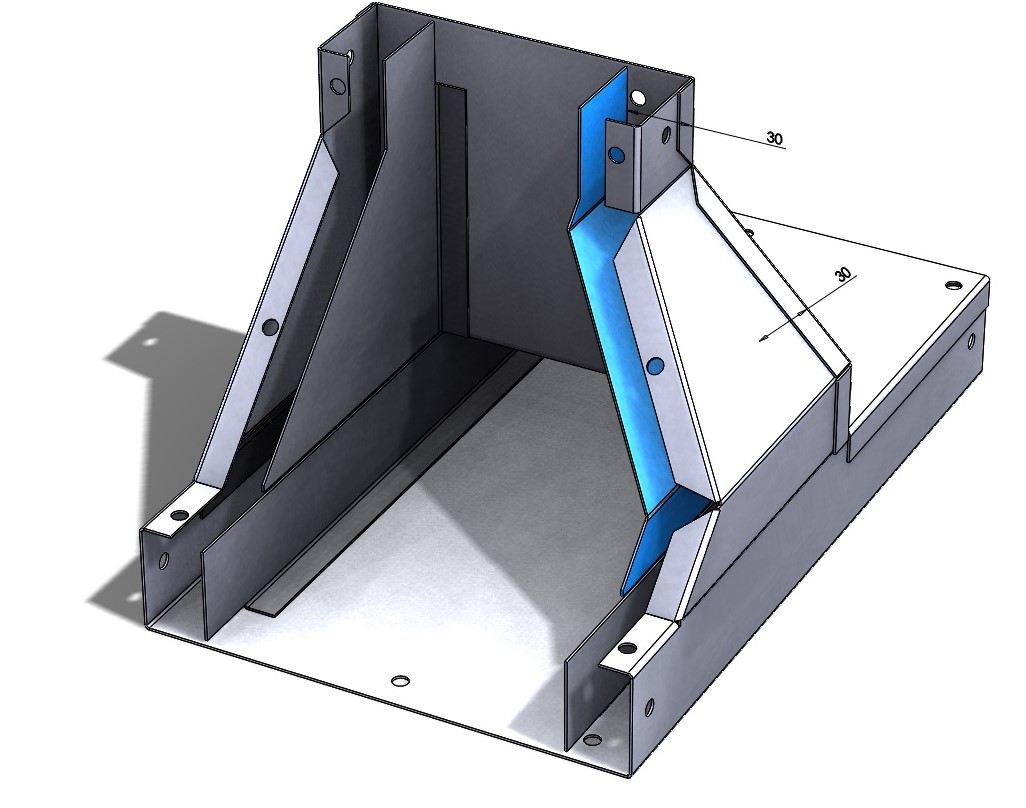

Being flexible and responsive can also pay huge dividends. For example, Armorduct has created a specialist section within its manufacturing plant that is dedicated to producing bespoke items. This means that lead times on these products has been dramatically reduced, as it does not rely on interrupting the manufacture of the company’s off-the-shelf ranges. It also means that dedicated experts from the computer aided design (CAD) team are available to work on bespoke solutions and even value-engineer standard production items to provide greater value.

Get serious

With growing awareness of climate change, end users are asking electrical contractors to source products from manufacturers and wholesalers that operate sustainability. This means they go beyond simply using more environmentally friendly materials here and there, and consider sustainability throughout the product lifecycle – in design, manufacture, packaging and delivery. A chain is only as strong as its weakest link, so manufacturer and wholesaler partners must be aligned in their net-zero commitments.

Cable management manufacturers increasingly reprocess and reuse materials where possible. Manufacturing plants should address their water and chemical management and use LED bulbs with automated sensors instead of fluorescent lights. Manufacturers should also endeavour to integrate sustainability into research and development activities, using computer modelling, analysis and prototyping prior to physical modelling, to reduce material waste. When prototypes are verified through several layers of quality control before continuing to the next step, it also ensures that incorrect iterations are revised prior to committing large amounts of raw materials.

Increasing demand for high performance and low maintenance in every aspect of construction activity is also driving growth in pre-fabricated cable management solutions. When considered against typical installation and implementation project costs, reduced waste and packaging, savings on on-site contractors and the benefits of guaranteed quality, it’s no wonder the use of pre-fabricated cable management is growing.

The time is now

There is a real need for manufacturers and wholesalers to reimagine how they can better work together. At its core, every manufacturer and wholesaler relationship should be a partnership and in order to get the most out it, both parties must be in alignment. Manufacturers must be proactive in developing customer relationships, offering innovative solutions and adding value through knowledge and service, while wholesalers must offer speed of response along with technical knowledge and a proactive approach to sales that provides genuine solutions for the entire supply chain.

For further information, click here