AFDDs have been getting a lot of attention following the publication in March of Amendment 2 to BS7671:2018 (18th edition of the IET Wiring Regulations). Jake Green, Technical Engagement Manager with Scolmore, looks at the technologies associated with AFDDs.

An arc fault detection device (AFDD) is a safety device which activates in the presence of series and parallel arc faults by monitoring the waveform (signature) of an arc. It does this by electronically analysing the waveform and ‘trips’ when the waveform falls outside of predetermined values.

The first Arc Fault Circuit Interrupter (AFCI) was patented in the US in 1980 and was described for use in the US National Electric Code (NEC) in 2008. In 2013 the Product Standard IEC 62606 was introduced and became a UK Standard that same year.

BS EN62606: 2013+A1: 2017 General requirements for arc fault detection devices states that the purpose of an AFDD is, ‘…to mitigate the risk of fire in final circuits of a fixed installation due to the effect of arc fault currents that pose a risk of fire ignition under certain conditions if the arcing persists’.

Electric arcs

The phenomena of electric arcing were first demonstrated to the Royal Society in London by the chemist and inventor Sir Humphrey Davy in 1801. Other studies followed and an electric arc can be considered to be:

‘An electrical breakdown of a gas that produces a prolonged discharge between two means of conduction.’

There are instances where arcing is a desired effect, such as when welding or plasma cutting. However, uncontrolled arcing due to a fault is undesirable.

Causes of arc

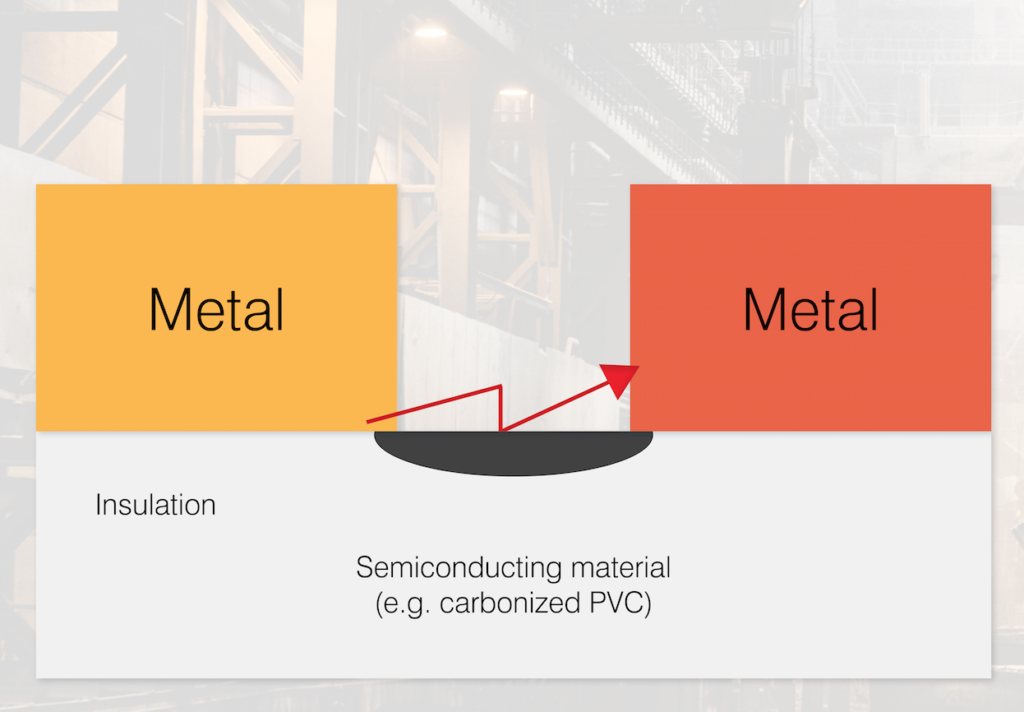

Contact arcs can result from either direct or indirect contact between metal parts which are moving relative to one another or have little conductivity, such as a loose electrical connection or a break in conductor.

To generate an arc is a complicated process, but principally an arc fault is a function of the voltage and the distance between the two points of contact. Initially, an arc is composed of metallic vapours (for example, carbon) and current can flow through the damaged section (Fig 1). As the current flows through a material that is a relatively poor conductor, heat is built up due to the heating effect.

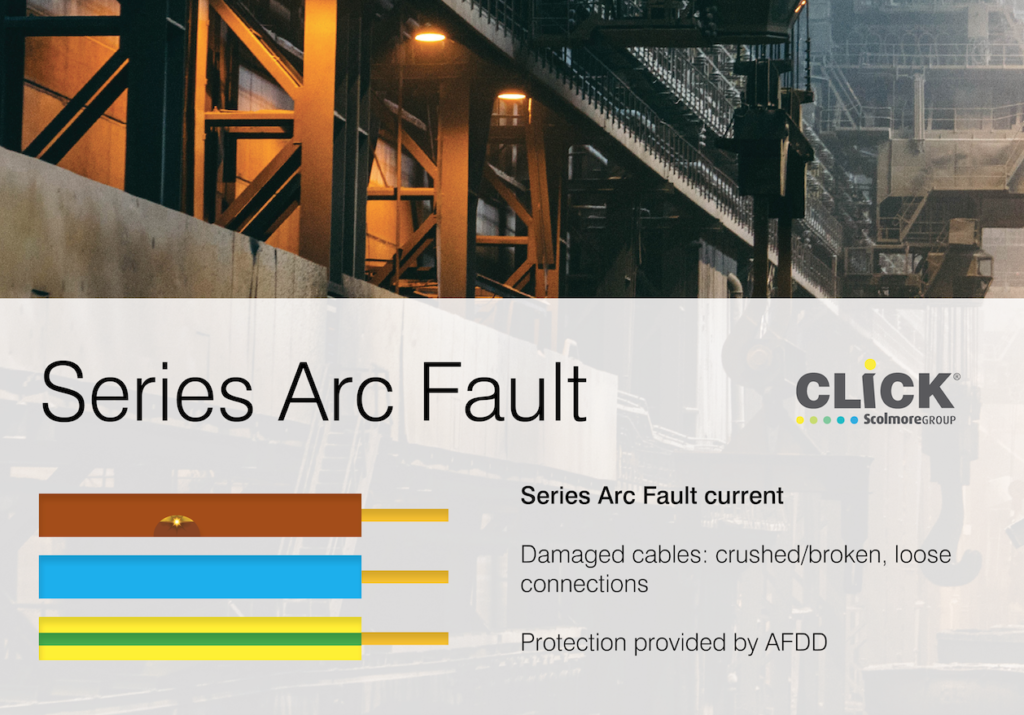

Series arc

Whilst it is possible for a stable arc to be formed with low currents, say less than 2A, there is insufficient energy to ignite the cable and hence, the probability of ignition is severely limited.

Most arcing faults detected by an AFDD exist in currents ranging from 3A to 10A, and these values reflect normal operating currents in domestic installation circuits.

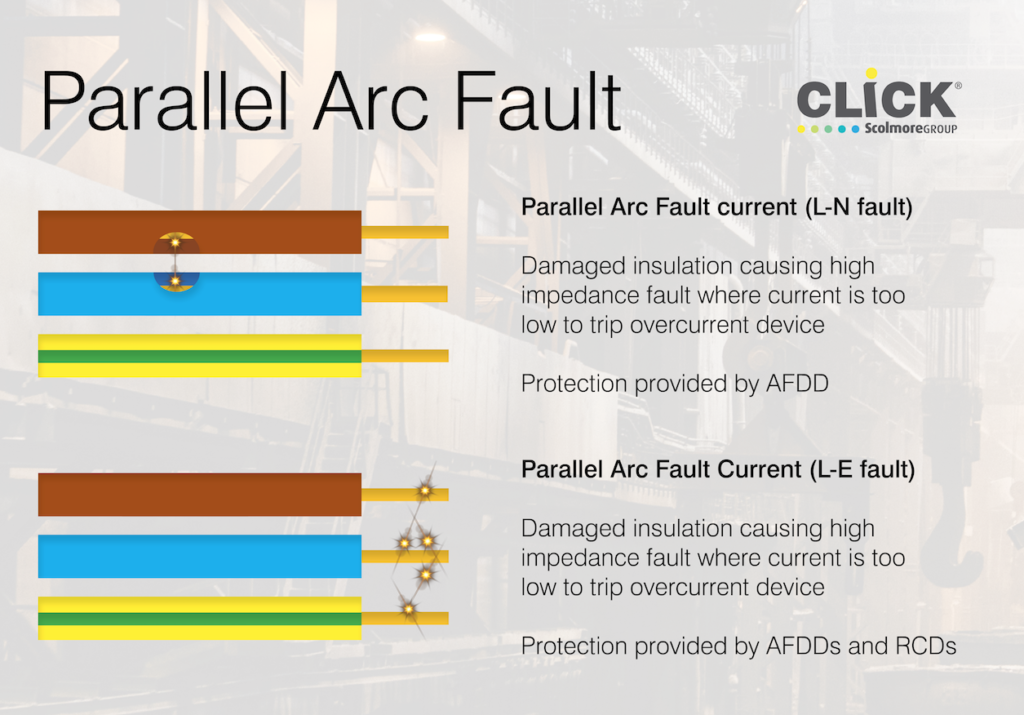

Parallel arc

In a parallel arc, insulation breaks down between two or more conductive parts that are normally separated: line to neutral, line to earth and neutral to earth. It is more likely that a parallel arc fault will operate a typical overcurrent protective device, such as a circuit-breaker or fuse than a series arc.

Means of detection of arc faults

Manufacturers differ in how they choose to conform to the requirements of the Standard, however. Scolmore applies three characteristics in complex algorithms which, when taken together, will cause their AFDD to trip. These are:

Noise – HF noise in the high kHz to the MHz region. This ‘noise’ is generated by the movement of the arc roots at the cathode. Whilst there are other sources of ‘noise’ which are naturally generated by electrical equipment operating normally, these are of a different nature and the algorithm filters them out.

Continuous – ‘noise’ must not be of a brief duration or very intermittent. It is only a continuous process that will lead to the creation of a fire risk and, therefore, where ‘noise’ is intermittent this will not lead to the operation of the AFDD.

Current variation – erratic variations in current and waveform distorting the typical sinusoidal waveform of the normal supply. A series arc will have an impact on the nature of the load current within a final circuit. At the point of arcing there will be an increase in heating with a corresponding variation in current. The AFDD algorithm will sense this changing current.

Unless all three elements are present the AFDD will not operate as it is unlikely a true series or parallel arc will be present.

Conclusion

It is well recognised that arcing can, and will, lead to fire. AFDDs provides additional protection against fire and is particularly beneficial when protecting final circuits supplying socket-outlets.

For further information, click here