The circular economy is growing in importance – that is widely recognised. But how can electrical wholesalers get involved? Nigel Harvey, Chief Executive of Recolight, examines the practical steps that can be taken beyond featuring or highlighting low energy or sustainable products.

Probably the fastest growing area in lighting, albeit from a low base, is the remanufacture, or upgrading, of lighting. This typically happens when a customer wants to move from fluorescent fittings to LEDs. Rather than simply remove the fluorescent fittings (to be trashed or recycled) with brand new LED fittings supplied, an increasing number of customers ask for the existing fittings to be upgraded instead.

There are many good reasons for doing this. Firstly, reinstating the same fittings means no further work is needed on the ceiling, with fixing points unchanged. Secondly, there may be cost savings. And thirdly, perhaps most vitally, the embodied carbon emissions are far lower.

For an increasing number of customers, that last point will be the most important. More and more companies are setting Net Zero and carbon emissions reduction targets. And reducing the embodied carbon (the carbon emissions involved in making and distributing a product) is an important part of that meeting that target.

And an increasing number of luminaire manufacturers are now able to provide LED upgrade modules that make the job very straightforward.

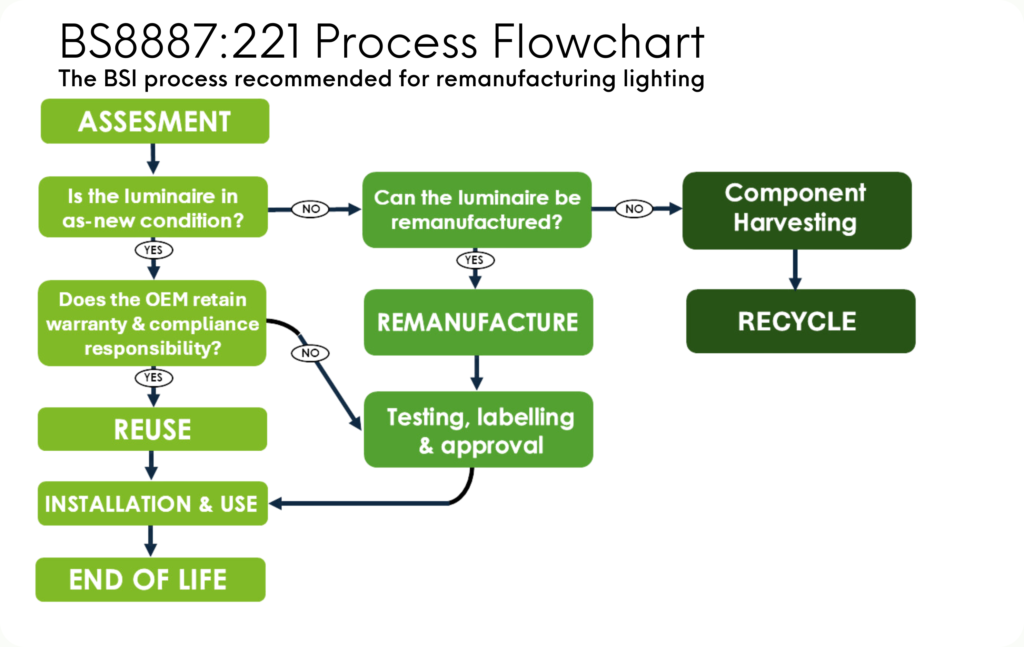

Remanufacture code of practice

This growing sector received a significant boost at the very end of last year, when a new specification was published by BSI. BS8887:221 2024 is the newly released code of practice for luminaire remanufacture.

It gives confidence to customers that remanufacture and upgrades are undertaken in a consistent and compliant manner. It has been developed over the last two years by a dozen or so individuals drawn from across the lighting industry.

New environmental metrics

Alongside the growth in remanufacturing, there has also been an explosion in the range of environmental and sustainability certifications. It is helpful for wholesalers to understand what they mean – and their limitations.

TM66

The TM66 specification is a way in which lighting manufacturers can rapidly assess the extent to which they have adopted circular economy principles in new products. It was developed by a Society of Light and Lighting (SLL) team and produces an aggregate, weighted score on a 0-4 scale to indicate the extent of circularity of a product.

The TM66 specification has undoubtedly encouraged companies to change what they make, and how they make them, to improve their scores, which has resulted in more products incorporating sustainability and circularity.

But it has significant limitations. It is very largely restricted to the UK. And although there is a third third-party certification scheme run by the LIA, it can be self-certified.

What’s more, a single digit is limited, given that strengths and weaknesses in a product are averaged out. So, TM66 is probably best seen as an entry level approach to sustainability. It gets the issue on the drawing board, and helps manufacturers demonstrate product circularity. But on its own, it is not enough to provide informed customers with the information they need. It is also unlikely to ever be a legal requirement.

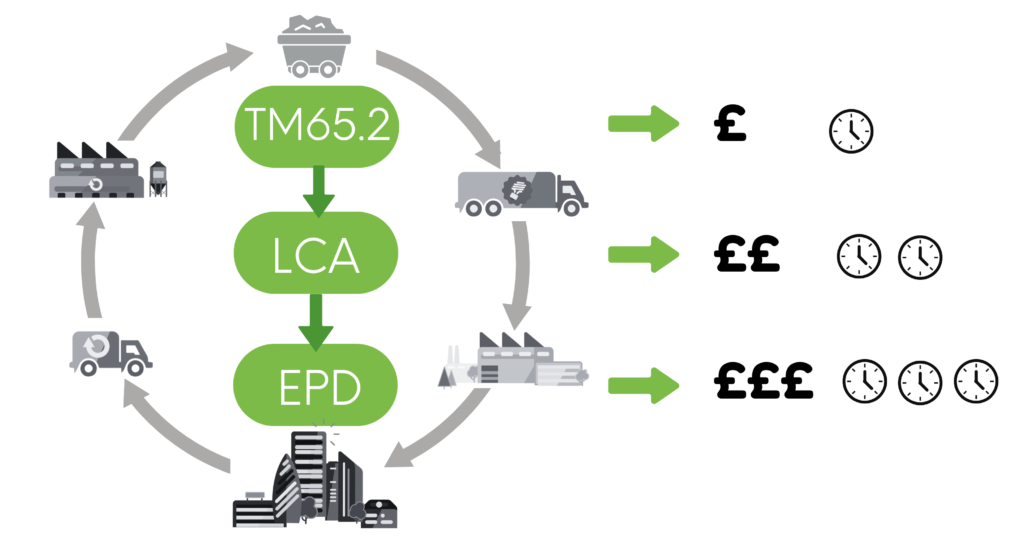

TM65.2

The TM65.2 specification provides lighting manufacturers with a quick way of determining the embodied carbon content of a new product. We can expect to see an increasing number of customers that will choose products, in part, based on embodied carbon. So, access to a simple assessment methodology helps suppliers respond to such requests. But as with TM66, there are some limitations. In particular, it is largely a UK-centred specification, can be self-certified, and is unlikely to ever be written into UK law.

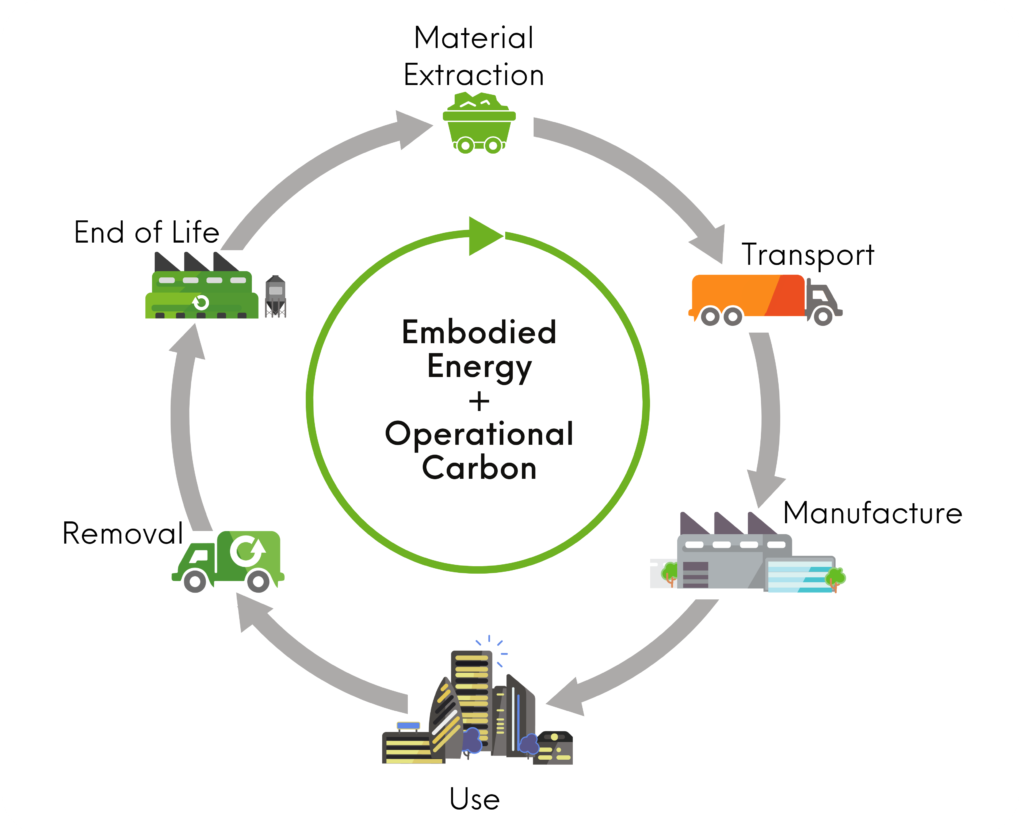

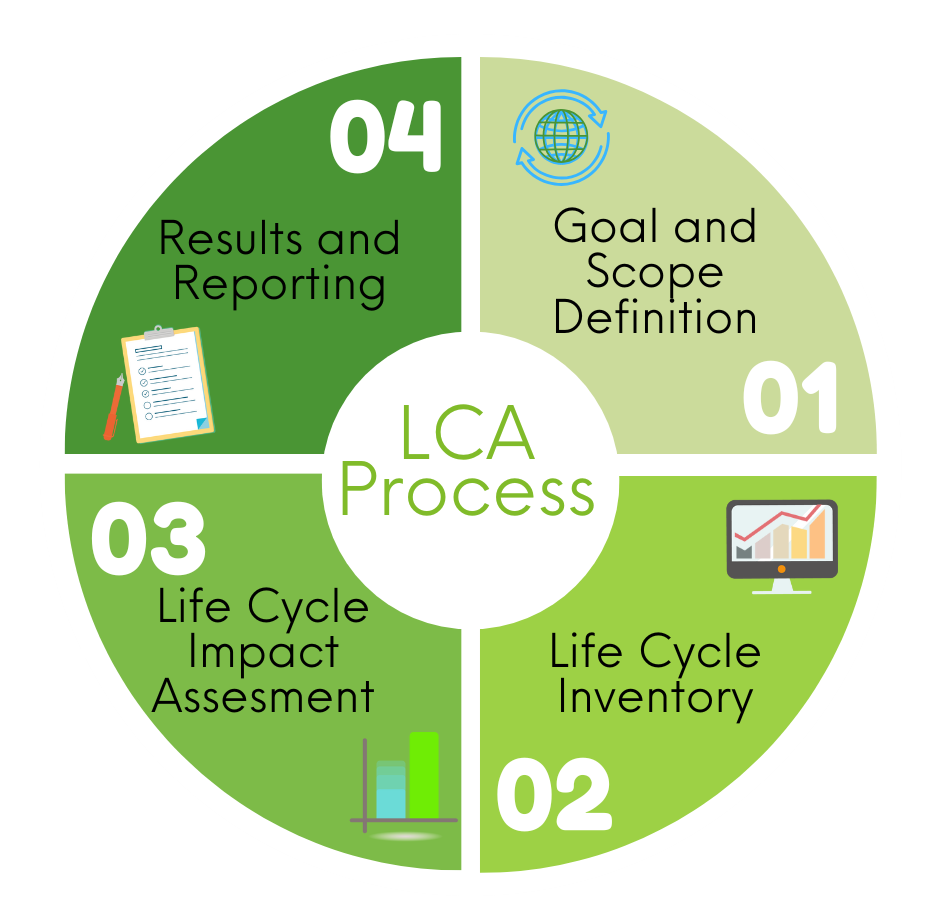

LCAs

A Life Life-Cycle Assessment (LCA) is a much more detailed analysis of the total environmental impact of a product. It extends beyond embodied carbon to include whole whole-life carbon (including the carbon emissions when a product is used), and also includes a number of other impacts, including water use, pollution and land use.

An LCA uses data to calculate the footprint of a product based on its intended life cycle. Unlike TM65, this includes a more comprehensive appraisal of end-of-life processes and their impacts. And vitally, the LCA methodology is internationally recognised.

EPDs

An Environmental Product Declaration (EPD) is a way to communicate the results of an LCA in a single document. EPDs are already very widely used internationally – not just in the built environment, but in many other sectors as well. They allow customers to compare the environmental performance of otherwise similar products. Vitally, they also present data in a standardised format allowing incorporation into a whole building LCA or whole project LCA. It seems likely that EPDs will, at some stage, become a mandatory requirement for certain product groups: for the medium term, and in the short term for companies looking to future proof their ranges, EPDs are likely to be the preferred option.

Summary

Sustainability is here to stay and will become an increasingly important consideration when customers choose products. For wholesalers, keeping abreast of these developments – and vitally working with suppliers that do so as well, is a very tangible way to contribute to the circular economy.

Find out more here

Find more industry feature articles here