Nigel Harvey is CEO of Recolight, the WEEE compliance and collection scheme for the lighting industry. Nigel outlines initiatives undertaken by Recolight to help the lighting industry adopt circular economy principles, and explains what wholesalers can do to support this response to the climate crisis.

We are all aware of the huge challenge the climate crisis presents to us all. The biggest changes needed are undoubtedly at Governmental levels, but there is a lot that can be done by businesses to make a difference.

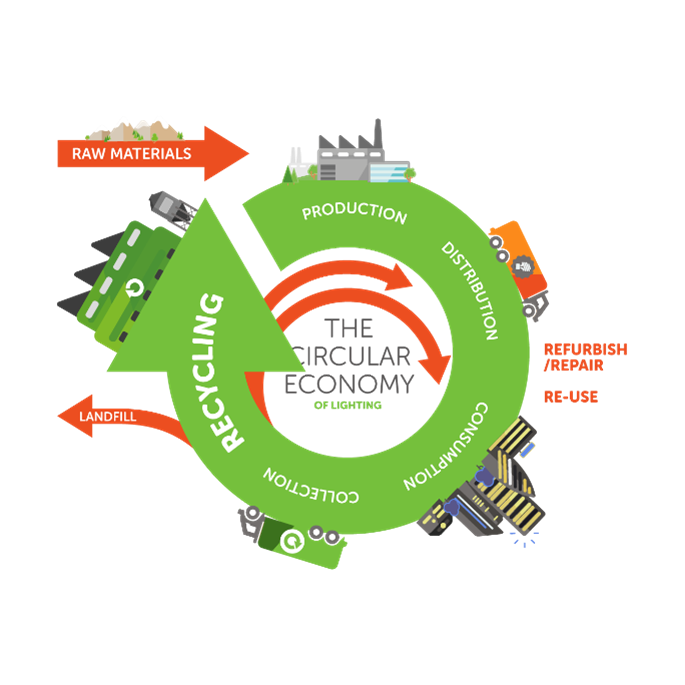

One crucial change that is needed is to fully embrace and adopt circular economy principles. In short, we need to keep products in use for longer, rather than simply discarding them, or needlessly recycling them. That improves resource efficiency, and saves the embedded carbon footprint associated with making new products.

A vital way of achieving this in the lighting sector is to make used fittings available for remanufacture when they are replaced. Re-use like this has much better environmental outcomes than recycling – the body of the fitting is retained, and the light source or control gear can be checked or upgraded.

Clearly for this to happen successfully in the UK, we need a number of changes:

- Customers and specifiers need to start to request used fittings. Pleasingly, we are already beginning to see examples of this.

- Manufacturers, or their subcontractors, need to develop the competencies needed to remanufacture fittings, and ensure they are still compliant with relevant legislation. Again, this is starting to happen. At Recolight, we are already aware of several members of our WEEE scheme, and other companies, that now see remanufacture as a viable business opportunity.

- Wholesalers can be a vital part of this process, by partnering with companies involved in reuse, and offering reused product for sale.

As a WEEE scheme, Recolight now collects additional information regarding used fittings that are being removed whenever one of our members is supplying LED luminaires to new projects. We will make that information available to companies that could remanufacture or upgrade the fittings and, upon request, will deliver the used fittings to the remanufacturer.

A number of specifications are being developed to facilitate the transformation to a circular economy. A BSI committee is working on a lighting version of BS8887, a standard for the remanufacture of luminaires. This standard will help companies remanufacture in a way that applies realistic approaches to product compliance, and will give end users the confidence that the product is suitable for use.

The Society of Light & Lighting and CIBSE have developed TM 66, a process to help producers of new lighting equipment demonstrate the extent to which they have taken circular economy principles into account in product design.

The Lighting Industry Association has issued Technical Statement LIA TS41, The Circular Economy: an interim guide, intended to help LIA members adopt circular economy principles. And Recolight has launched new services to whenever possible redirect the used lighting equipment the company collects on behalf of its members away from recycling, and towards repair and remanufacture.

This year we can expect to see further growth in circular economy approaches in the lighting industry. We will see more companies designing lighting products for a circular economy. But it will also mean more end users willing to consider product re-use, remanufacture and upgrades, rather than complete product replacements. Some companies will also start remanufacturing operations – taking in used product and upgrading it ready for resale.

The climate crisis is, without doubt, the biggest challenge humanity has ever faced. Facilitating the re-use of used luminaires is one small way in which our industry can respond to this challenge.

To find out more about Recolight click here