Paul Allen from power distribution specialist, CMD, discusses the opportunity for wholesalers to provide an alternative solution when shallow or uneven floor voids make powertrack unsuitable.

Over the past 30 years, the amount of tech used in commercial buildings on a day-to-day basis has increased dramatically as working practices have made occupiers more and more reliant on IT equipment and the need to charge portable devices. This means more sockets are required across the floor plate, with sufficient capacity for resilience and futureproofing.

In new builds, floor voids are usually designed with sufficient capacity for the level of services required. But even here, obstacles in the void, architectural features or a focus on maximising headroom can result in challenging congestion or inconsistencies in the floor void.

In existing buildings, constructed before technology became such an integral part of the way we live and work, capacity in the floor void can be more of an issue. Heritage buildings in particular often feature varying void depths but a consistent approach to installing the power distribution is preferred throughout.

It’s an issue that electrical specifiers and contractors face repeatedly when planning the electrical infrastructure for commercial buildings. While they might prefer to use a busbar powertrack system because of the speed and ease of use it offers, along with plug and play installation and future flexibility, shallow or uneven floor voids often mean a powertrack system is not suitable. This is because powertrack systems usually require floor void depths of 50mm or more – CMD’s Betatrak powertrack system is just 51mm – with additional clearance to allow the building owner, occupier or facilities management provider to access tap-offs for maintenance or reconfiguration.

While powertrack remains by far the most popular and obvious choice for most projects, when it is not suitable, specifiers often assume that they must fall back on a choice of two onerous options: either to raise the floor and increase the void, or to opt for a hard wired electrical network. Both of these choices would add time to the programme and raising the floor could compromise headroom and heritage features too.

There is an opportunity for wholesalers to add value to relationships and win business by offering customers a third option: a power hub system.

Adaptable, compact and compliant

Designed to offer plug and play ease and speed of installation comparable to powertrack systems, along with similar flexibility and futureproofing benefits, power hub systems are an ideal alternative where space is limited. They combine compact hub units with flexible metal conduits or ‘umbilicals’, which connect the hubs together to create the electrical distribution network. The flexible metal conduits provide cables with mechanical protection, allowing compliance with Wiring Regulation 543.7 “Earthing requirements for the installation of equipment having high protective conductor currents”. They also protect cables from dirt ingress and rodents, ensuring a similar level of resilience to powertrack systems and ensuring that the electrical distribution system offers a low maintenance, fit and forget solution

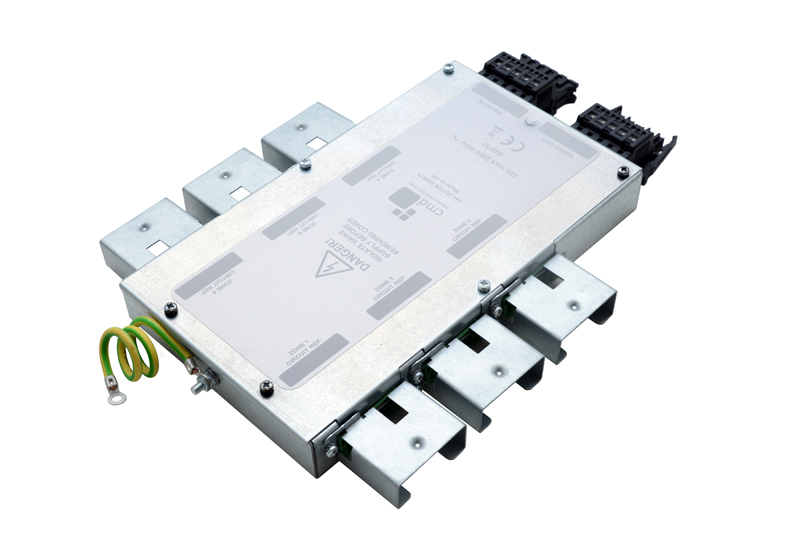

Power hubs are specifically designed for buildings where a conventional powertrack system cannot be installed due to lack of void depth or obstacles in the void. Not only are the units themselves compact – the CMD Power Hub system is just 38mm high – making them suitable for voids where height is limited, but the tap-offs are located to the side rather than above, which means that no additional height clearance is needed for the removal, maintenance or addition of tap-offs.

In a straightforward installation, the linear nature of powertrack systems is very useful for creating neat parallel runs of power distribution, with a scalable layout that can be replicated on every floor. Where there are obstacles in the void, however, it can be difficult for contractors to route lengths of track around them because they can only be installed as straight lengths, which need to be laid flat. Where this is the case, the flexibility of a hub system’s umbilicals enables obstacles to be dealt with easily.

Power hubs are also ideal for customers specifying power distribution systems in buildings where the slab is uneven. In this scenario, if powertrack were to be used, it would have to be installed so that lengths of track were lying at different heights or angles, preventing consistent connections. This could cause issues on the distribution network, compromising entire circuits. Conversely, when using a power hub system, contractors can place the hub unit on a flat area of the slab and the performance of the cables within the flexible umbilicals is unaffected when they are routed across uneven surfaces.

The flexibility of the metal conduit can also be useful for installations where the service void is very congested because it can be routed around other services without compromising the floor box layout or the integrity of the network.

For all these reasons, where there is any question mark over the suitability of powertrack, there is an opportunity to offer a hub system because this will not only overcome specific building challenges but also offers the contractor ease of installation along with ease of maintenance, future flexibility and compliance for the developer/building owner.

CMD Power Hubs are available in 4-way and 6-way units, which can be wired in a series circuit in the required configuration. Tap-offs are made to the side of the power hub unit, using BS EN 61535 compliant connectors in a metal housing to ensure a secure and safe tap-off connection. A choice of tap-off units allows electrical supply to be routed to the required locations, regardless of how densely populated the floorplate will be, while minimising the number of hub units required, thereby providing a cost effective, space efficient and fast installation solution.

Additional hub units or tap-offs to existing units can be retrofitted to the installation at any time, providing the flexibility needed in contemporary commercial buildings for changing occupier requirements, change of occupier or change of use. No additional space is required for plugging in or unplugging tap-offs and multiple power hubs can be configured together on a single circuit.

Creative thinking

Powertrack has become such a ubiquitous solution for plug and play power distribution installations that specifiers can be nonplussed when it is not suitable. By offering a power hub system as an alternative, electrical wholesalers can offer customers comparable benefits.