It wasn’t that long ago that you’d find expensive cable management systems with cables installed, operational and apparently secured using cheap cable ties rather than cable cleats. Thankfully, things have moved on a great deal since those dangerous days, but there are still plenty of pitfalls to beware of. Lee Frizzell, Technical Director of CMP Products, offers advice on what to consider when specifying and installing cable management products.

From our perspective as a leading manufacturer of cable glands, cleats and accessories, we do have very specific areas of expertise within the cable management arena – namely the operational safety of the system once installed and the delivery of the peace of mind that it won’t cause untold damage in a short circuit situation.

Choices

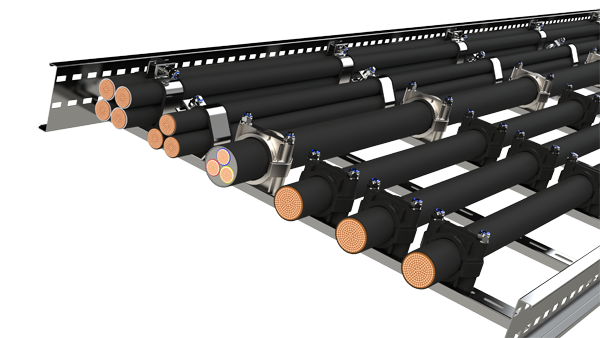

It is though worth nothing that any element of a cable management system needs to be carefully considered, and products selected and chosen wisely – whether it be a choice between cable ladder or tray; the depth of channel; the chosen product’s weight bearing capacity; the cable formation; corrosion resistant capabilities etc. One wrong choice or the selection of an unproven product made on price alone could undermine an entire system and lead to costly maintenance, repairs and possible catastrophic failure.

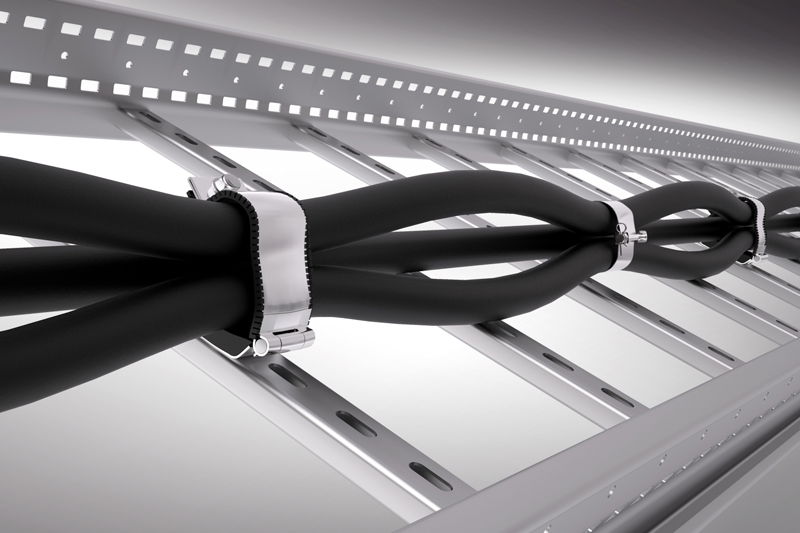

When it comes to cable cleats and working with CMP, we always aim to get across the key fact that their importance must never be underestimated. Cable cleats are safety critical products that need to be correctly specified to safely secure electrical cables not only during normal operating conditions, but also ensuring they are able to withstand extreme dynamic electromagnetic forces during a short circuit without sheath damage.

Effective cleating of cables by using a tested, proven product ensures the continuation of potentially vital electrical supplies and prevents cables leaping out of their containment systems during a short circuit, which would pose a very real threat to the building’s integrity and the lives of those in the vicinity of the affected installation.

Put simply, for any electrical installation to be deemed safe, cables need to be protected and restrained by devices proven to withstand the forces the cables generate – especially during a short circuit. This is exactly what our cable cleats are designed and tested to do.

Cleat considerations

There are a variety of things to consider when specifying cable cleats, but two key points that could make all the difference are:

- Trust – There are lots of cable cleats out there and it’s fair to say they can look very similar and claim to have very similar attributes. Therefore, it’s important to specify with confidence. You’d think twice about buying an expensive new phone from an unknown telecoms manufacturer, so don’t do the same with cable cleats. Look at the company behind the product; their technical expertise; the post-sales support they offer; where else have their cleats been used and are any of the installations similar?

- Testing – Will the cable cleats you’re considering be up to the job? Some manufacturers will highlight the strength of their products based solely on a static mechanical tensile test. Unfortunately, this can be misleading as the forces applied in this type of test are applied in a slow and controlled manner, unlike in a short-circuit fault, where dynamic forces are applied almost instantaneously and oscillate in every direction. A short circuit test really is the only reliable way of knowing a cable cleat can withstand a specific set of fault conditions and is essential for anyone, anywhere to specify with confidence.

Trust and testing carry over into cable glands and accessories, where they really should be at the heart of every specification decision.

Also necessary for consideration across the cable management spectrum, are the environment of the installation and fire safety properties of the products. For environmental compatibility, you must consider everything from operating temperatures to UV and corrosion resistance. And when it comes to fire resistance, cable cleats must have the same flame retardancy as the cable they’re securing.

Cable glands

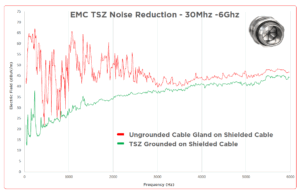

Cable glands require additional consideration due to the issue of electromagnetic interference (EMI) – something that is governed by the EMC 2014/30/EU Directive. This enforces limitations on all electrical and electronic equipment that may cause or be affected by EMI and requires that products must not generate unwanted electromagnetic pollution or interference and that they must be immune to a reasonable amount of noise pollution or interference.

However, there is a significant oversight at the point of cable entry into an electrical enclosure. By adding openings in enclosures, pathways are created to allow noise to breach the shielded enclosure. Unterminated or poorly terminated cable shields can allow noise to be carried into the enclosures, acting as antennas to radiate noise onto sensitive circuits. Grounding the cable shield effectively inside a cable gland at point of entry eliminates a potential noise pathway and reduces the risks of radiated emissions being carried into the enclosure.

Cable glands that employ a robust 360° circumferential termination of the cable screen, shield braid or armour (e.g. with a cone and clamping ring, or a dedicated EMC continuity device) in their metallic body, contribute to the electromagnetic compatibility of installations through reliable low impedance connections. Stats that are backed up by a number of industry studies into the role they can play in EMC protection.

It’s therefore vital that specified cable glands have been tested for attenuation of EMI and provide the protection required. Underspecified cable glands could cause significant issues to the integrity of the electrical systems on which they are fitted.

Proven solutions

When it comes to improving electrical safety, whether it be with the intention of protecting people, power supplies or data, it’s imperative that every potential step is taken to ensure the systems are the most robust they possibly can be. As such, suitably proven cable management products need to be given careful consideration so that they don’t become the weak link in system – causing operational failure and tarnishing reputations.

For further details, click here

Find more industry features here