Having the right power tools to hand can help significantly improve efficiency on site. Here, Kevin Brannigan, Marketing Manager at Makita, highlights some of the factors that wholesalers should be aware of when recommending products to customers.

Power tools by their nature speed up time consuming or laborious work. However, not all power tools enable the same level of efficiency in day-to-day tasks. Cordless tools will typically offer greater efficiency when compared to corded alternatives. This is because battery powered tools provide flexibility and ease of use by eliminating the need to find a power source in the work area and manage the safe routing of cables.

Due to battery and tool innovations, customers have never had a greater choice of cordless products, including for the most demanding tasks. However, when recommending cordless tools, there are a number of specific features that will be beneficial to customers to help them streamline their work and improve productivity.

Single battery platform

Significant efficiency gains can be made by selecting tools that share a common battery platform. The batteries can simply be swapped between tools as required, rather than needing to find the right battery for the right tool when moving from one task to another. It also means simpler recharging as the same charger can be used for all batteries used on site. As an example, the Makita 18V LXT range features over 270 products including drills, impact drivers, circular saws, metal saws, routers, drywall cutters, multitools, wall scanners and work lights.

Advances in both battery and tool technology means that the run times offered by leading manufacturers are now far greater than with previous generation products. However, when charging is necessary, choosing a battery platform that has been engineered for rapid recharging times means less wasted time and greater productivity. For example, Makita 3.0Ah 18V LXT batteries charge in as little as 22 minutes while the 6.0Ah version takes just 55 minutes. Additionally, there are ‘power source kits’ available that include several batteries and the required charger to enable users to always have a spare battery to hand, eliminating any need to wait for battery recharging. This also allows customers to purchase ‘body only’ tools as they expand and upgrade their kit in the future.

Brushless motors

Another key tool feature to be aware of is brushless motors. While motors with brushes are effective, the motor is driven by contact between the carbon brushes and the rotary electrical switch on the rotor. This contact causes friction that generates heat and wastes energy. It also causes wear of the brushes, which must be periodically replaced throughout the life of the tool.

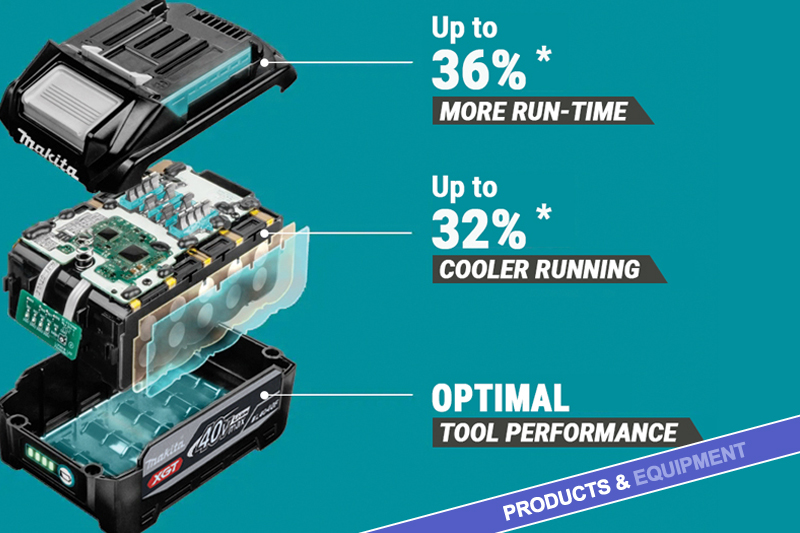

In contrast, a tool with a brushless motor is driven using contact-free electromagnetism. When the tool is activated, the on-board electronic circuit sends electric currents to convert the copper coils within the motor into electromagnets. This creates north and south magnetic poles that attract and repel the permanent magnets on the rotor shaft to rotate it continuously. By eliminating the friction, and therefore the wasted energy, a brushless motor can operate more efficiently. This type of motor can also produce more torque per weight, meaning less power is needed to achieve the same results. The result of this is that a tool with a brushless motor can extend run times by up to 50% per battery charge. This means greater productivity and fewer recharges throughout a day.

Optimal power delivery

When carrying out demanding tasks, it is important to ensure that the tools can match the load requirements. Products from leading manufacturers may include technologies that allow the tools to adapt to the resistance of the material. For example, Makita’s Automatic Torque Drive Technology (ADT) automatically adjusts the speed and torque based on the load conditions during operation to ensure optimum performance.

Portable power sources

Another way that efficiency can be improved is by enabling significantly extended run-times with portable power supplies. For example, the Makita PDC1200 and PDC1500 backpack-mounted power sources provide 33Ah and 43Ah of power respectively for uninterrupted operation. These can be connected to a wide variety of machines via adaptors that slide into the battery mounting on the tool or using a direct connection on compatible products.

Streamlining dust management

Although best practice dust management is sometimes sacrificed in favour of getting a job done quickly, it is absolutely essential. This is particularly true when completing a task that generates respirable crystalline silica (RCS). These tiny particles are extremely hazardous to health and are produced when materials like concrete, masonry and stone are cut, drilled or otherwise processed. Therefore, tool technologies that can streamline dust management are worth recommending to customers.

One feature that can help achieve this is ‘auto’ functionality on dust extractors. This has been common on extractors with power take-off where corded tools can be connected to the extractor to start it when the tool is activated. However, it is now possible to achieve the same with cordless tools. For example, the Makita Auto-Start Wireless System (AWS) connects cordless tools to compatible dust extractors via Bluetooth to run the extractor when the tool is in use. For customers who are using an older model of extractor without the built-in connectivity, there are adapters available that allow tools to be connected wirelessly to any mains powered extractor that has a power take-off facility. On the other hand, if customers are looking to add a new extractor to their kit, there are cordless options available for improved ease of use and flexibility.

The correct choice of power tools can make a significant difference to the user’s experience and the level of productivity and efficiency they can achieve. Although the specification of two tools may look similar, it is important to look at the built-in tool technologies and other factors to make the best recommendation.

For further product details, click here

Find more industry feature articles here